Our top picks

Get extra value when you stock up on these recommended insulation products.

Brands you trust

For the best results, every time, we stock high-quality brands that builders love using.

Popular products

Explore the best-selling Stud & Track products that are in demand with our customers.

Discover more

Tap into our expert advice and support to find the products.

Your Best Options for Stud Wall Insulation

Sustainable Loft Insulation Solutions for The Professionals

Loft Insulation Installation: Trade Tips and Common Mistakes

Frequently asked questions

Unfortunately, we do not offer a customisation service. However, we do supply tools on our website to effectively cut these materials to the desired dimensions.

Yes, we provide reliable delivery services for stud and track across the UK. The estimated delivery time depends on your location and the specific products ordered. Check out our Delivery Options page for guidance.

Yes, all our products meet or exceed industry standards and building codes. This ensures your construction is not only efficient but also in compliance with regulations.

Timber Studs

Timber studs continue to be a construction staple which offers several advantages over other materials like steel or concrete. Wood is a renewable resource that can be sustainably harvested, making it a more environmentally friendly choice compared to steel studs.

Using timber studs can also help streamline the construction process. Wood studs are relatively lightweight and easy to work with using basic hand tools. You can cut and assemble timber framing quickly on-site. The studs can be precisely cut and engineered for strength while minimising excess material use. In contrast, working with heavy steel components requires specialised equipment and more handling.

Timber has natural insulating properties that can enhance a building's energy efficiency. The wood helps block heat transfer through the walls, reducing heating and cooling loads. Its insulation value is improved when wall cavities are filled with batt or blown-in insulation.

Timber also absorbs airborne sound better than metal studs. This gives interior walls with timber studs superior acoustic insulation. The flexibility of timber is another benefit because wood can better tolerate movement and settling in buildings over time compared to rigid steel.

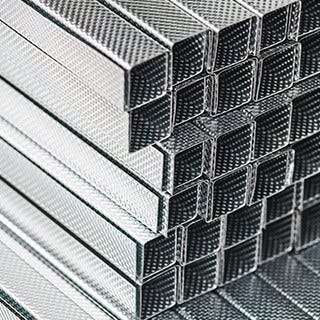

Metal C Stud

Metal C studs have become a popular alternative to timber studs for wall framing. C studs are made by folding thin galvanised steel into a C-shaped channel.

Metal studs do not warp, twist, or shrink over time like wood. It prevents cracked plasterboard or other issues that can occur as timber framing settles. The steel channels remain straight and intact for the lifespan of the building.

C studs are also well-suited for load-bearing walls in multistory structures. Steel has a higher strength-to-weight ratio than wood, allowing C studs to support greater loads in vertical wall applications. This facilitates taller walls and bigger buildings when using metal framing.

Installing C stud walls is a relatively quick process. The lightweight steel components are easily lifted and fastened into place with screws. There is no need for complex joints or time-consuming cutting like when framing with wood, significantly reducing construction time frames.

Metal I Stud

Metal I studs tend to have an increased strength over C studs. This allows a wider distance between supports, making them well suited for interior non-load-bearing walls.

The shape of I studs makes it easy to construct unique framing like arched or curved walls. The studs are flexible and can be bent into various non-standard shapes. Like C studs, I studs do not shrink or warp over time, preventing cracks or raised nail bumps like those that can develop with wood framing.

I studs offer excellent fire resistance and will not combust. This added safety benefit makes I studs preferable for firewalls or partitions between living and working spaces.

Metal U Tracks

Metal U tracks are used to form the top and bottom channels that studs fit into. The tracks are made by folding sheet metal into a U shape to create the channels.

U tracks provide a stable base to securely anchor stud framing. The channels contain and align the studs, preventing twisting or buckling. This allows the walls to withstand lateral and vertical loads. U tracks also aid alignment during construction, keeping studs plumb and properly spaced as wall framing is assembled.

U tracks help reinforce openings like doors or windows in steel stud walls. Extra studs can be secured in the channel around openings to provide additional structural strength. The channels provide a convenient attachment point to fasten trim, plasterboard, or other finishing materials to the framing.

These metal tracks are flexible to accommodate wiring and plumbing. The channels create a void space for running utilities through without drilling through studs. This utility routing is easier than working around wood framing.

Stud Channels

Stud channels are metal framing components used to create floor joists and ceiling framing. They consist of C-shaped steel channels typically made from cold-formed galvanised steel.

Stud channels will not burn or fuel a fire like wood joists. This added safety makes metal channels ideal particularly for multistory buildings to slow fire spread. Steel also handles high temperatures better, reducing the risk of framing failures in a fire.

Stud channels allow long, open spans without intermediate supports. The high strength-to-weight ratio of steel enables the channels to handle greater loads and span longer distances than wood. It facilitates versatile room layouts without columns interrupting space.

The uniform shape and size of stud channels simplify installation compared to wooden framing members. Metal channels are assembled using simple screw or bolt fasteners. Prefabricated stud channels also speed up construction versus labour-intensive traditional framing. Also, steel stud channels will not warp, twist, deform or shrink over time.

Resilient Bars

An important tool for reducing sound transmission between rooms, resilient bars help block airborne noise like voices, music, or television sounds from passing through walls. The bars disconnect the plasterboard from the studs and absorb vibration. As a result, this prevents noise from flanking up through the studs for superior sound insulation.

Properly installed resilient bars can lower sound transmission through walls. It significantly reduces nuisance noise levels and is a cost-effective soundproofing solution compared to rebuilding walls. In addition to walls, they effectively reduce footstep noise travelling through ceiling and floor spaces. The bars absorb impact vibrations that would normally transmit to the ceiling below, creating a buffer zone for quieter rooms underneath.

Metal Stud Accessories

Metal stud framing relies on a range of accessories to connect, reinforce and finish interior wall systems. One essential accessory is clip angles. These small L-shaped steel pieces mechanically fasten studs to floors, walls, and ceilings. Clip angles provide a strong, simple connection to anchor framing. They allow adjustment during installation to plumb vertical components.

Backer plates offer structural reinforcement and rigidity to wall openings. These steel plates attach around door or window headers, spreading loads from above around the frames. Backer plates prevent deflection that could otherwise cause cracks in finishes.

Insulation spacers are vital for proper thermal and acoustic performance. These small stands offset studs from exterior sheathing to allow cavity insulation. Spacers also facilitate consistent insulation thickness and prevent compression.

Bridging components connect studs across cavities to restrain twisting or bowing. These lateral braces typically clip or screw into webs. Proper bridging enables studs to resist shear loads as a unified system. Also, fasteners and connectors integrate accessories into the framing system. Self-tapping screws and metal tabs all help transform individual steel components into a sound structural frame.